Heating and lighting with lethal gas

Anderlues

Whilst in the past, miners lived in fear of firedamp, electricity producers in Anderlues are now using it legitimately, otherwise they risk losing it.

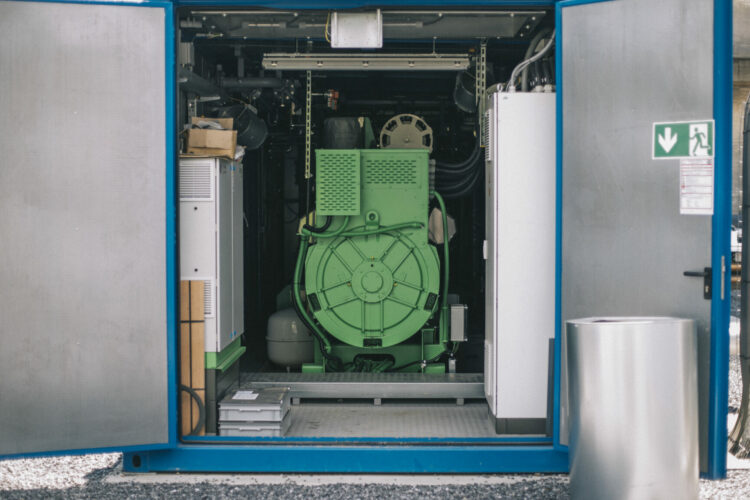

In Anderlues, on the old mining wasteland around Rue Jules Destrée, two containers linked to a series of pipelines have been set up alongside the coal mining tower. This facility, set up by Gazonor, a subsidiary of Française de l’Energie, is what supplies heat and electricity to 1,800 homes, all using firedamp.

Gas: use it or lose it

Firedamp, a toxic gas when inhaled by humans, is naturally released from coal. Previously, it was used to detect the presence of coal and workers used it as a guide when digging underground tunnels. This activity has since ceased, and the tunnel entry points have all been sealed off. As far as the gas is concerned, it still naturally propagates in the tunnels wherever space allows.

Over the years, there has been a noticeable build-up of pressure caused by the firedamp in these tunnels. This means there is a greater risk of the gas seeping out into the open air. “This gas, which we call lethal gas, is meant to disappear into nature in a highly polluting manner,” explains Yann Fouant, project manager at Française de l’Énergie.

The solution to this build-up of gas pressure is to limit pollution by processing and finding uses for it.

A home-grown energy resource

This is why the company has decided to invest in these former coal mining sites: the underground parts of them, to be precise, and to make use of the firedamp. The aim is twofold: to avoid leaks and produce energy. “With firedamp, we can produce electricity, heating and gas. Processed firedamp is far less polluting than when it seeps out into the open air, as we have seen on the former coal mining sites in Northern France,” he goes on to say.

This energy, which the company is calling ‘green energy’, occurs naturally in our soil, mainly in the basin of Hainaut, from Mons to Charleroi. “It’s a local resource. Who would have thought there would be such a rich source of energy in our back gardens?” he adds with a chuckle.

(Nearly) 100% local

A pipeline spanning over 150 metres crosses a concrete slab before disappearing underground. This pipeline is what transports the firedamp from the tunnels to the surface in a controlled way. The tunnels stretch to over 1,000 metres in depth and harbour enormous quantities of gas. “Currently, the shafts are too highly pressurised; in other words, the compressed gas emerges freely from the pipeline,” explains Yann Fouant.

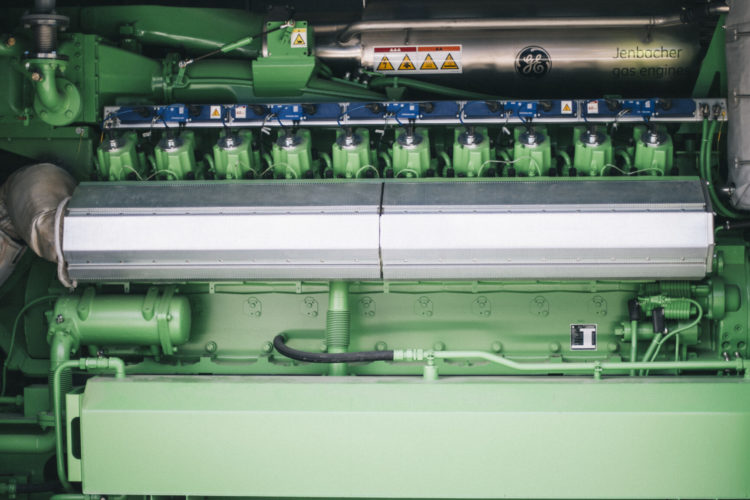

After having been filtered and brought to the same pressure level as the pipes, the gas flows into two large combustion engines to be transformed into electricity and fed into the electric grid.

These are the first two cogeneration machines in Belgium.

The energy’s journey between the harvesting of the raw material and its distribution is therefore very short. “The gas only has to travel about thirty metres before it is ready to be used. Nothing is lost and no energy or costs are required to transport the gas. This keeps the carbon balance as neutral as possible,” explains the project manager. “Only the engines are imported. The facility is installed and maintained using local resources.”

About twenty jobs have been indirectly created around the extraction site. These include the security guard service, repairs, maintenance and installation of machinery.

High energy potential

This extraction area was inaugurated last May. It is capable of supplying gas for 25 to30 years. The next steps consist of building more engines. “Given the quantity of gas, we could think about installing up to 6-7 engines over about twenty years,” he explained.

One engine currently supplies electricity and heating to 900 homes.

The company would also like to develop two other energy inputs: connecting to the gas network to use firedamp without having to process it, and use the heat produced by the engines. “We might think about developing a heating grid or use this energy to heat greenhouses or dehydrate agri-food products, for example.”

The Greater Charleroi Metropolitan area has other mining sites with similar energy potential which are currently being explored by the company.

Contact :

Ancien site de charbonnage

Rue Jules Destrée

6150 Anderlues

La Française de l’Energie

Espace Pierrard

1, avenue Saint-Rémy

57600 Forbach (France)

+33 (0)3 87 04 32 11

contact@francaisedelenergie.fr

www.francaisedelenergie.fr

©Photos/Alex Dossogne